- Get link

- X

- Other Apps

- Get link

- X

- Other Apps

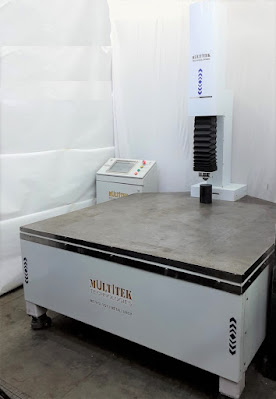

Fully Automatic Digital and Customized Rockwell Hardness Tester

What is Hardness Testing in Material Science and Engineering?

We at Multitek Technologies excited to share the

knowledgebase on Rockwell Hardness Tester. In the world of material science and

engineering, understanding the mechanical properties of materials is crucial

for ensuring their quality and reliability in various applications. One of the

key properties that engineers and manufacturers often need to measure is

hardness. Hardness is defined as the resistance of a material to deformation,

indentation, or scratching, and it plays a significant role in determining a

material's suitability for specific uses.

Hardness

testing is a widely used method for quantifying the hardness of materials.

It involves applying a controlled force or pressure to the surface of a material

and measuring the resulting indentation or penetration. There are several

methods of hardness testing available, each with its own advantages and

limitations. One of the most popular and widely used methods is the Rockwell

hardness test.

Why Rockwell Hardness

Tester?

The Rockwell hardness test is a non-destructive testing

method used to measure the hardness of metallic materials. It is based on the

depth of penetration of an indenter into the material under a specific load.

The test is named after its inventor, Stanley P. Rockwell, who developed the

method in the early 20th century.

The Rockwell hardness test

is known for its simplicity, speed, and accuracy, making it suitable for a wide

range of applications across various industries. It is particularly well-suited

for quality control and materials testing in manufacturing environments.

What are the Principles

of the Rockwell Hardness Tester?

The Rockwell hardness test works on the principle of

measuring the depth of penetration of an indenter into the material under two

loads: a minor load to establish a reference position (preliminary load), and a

major load to complete the test (additional load). The difference in

indentation depths between the two loads is used to calculate the Rockwell

hardness number.

The Rockwell hardness scale is defined by a combination of

the indenter type (diamond or ball) and the applied load. There are several

Rockwell scales designated by letters, such as HRA, HRB, HRC, etc., each

suitable for different types of materials and hardness ranges.

Components of a Rockwell Hardness Tester

A typical Rockwell

hardness tester consists of several key components:

Indenter: The

indenter is the tool that is pressed into the material to create the

indentation. In Rockwell testing, the indenter can be either a diamond cone or

a hardened steel ball, depending on the hardness scale being used.

Anvil: The anvil

provides a stable surface against which the material being tested is placed. It

ensures that the material is properly supported and prevents any deflection

during the test.

Load Application

System: The load application system applies the predetermined loads to the

indenter. It typically consists of a mechanical or hydraulic mechanism that

controls the application of the minor and major loads. Feel Free to Navigate

about Multitek’s

Other Products/Machines

Depth Measurement

System: The depth measurement system accurately measures the depth of

penetration of the indenter into the material under the applied loads. This

measurement is crucial for calculating the Rockwell hardness number.

Display and Readout:

The display and readout system provides the results of the hardness test in the

form of Rockwell hardness numbers. It may include analog or digital indicators,

depending on the model of the hardness tester.

Procedure for Performing a Rockwell Hardness Test

Performing a Rockwell

hardness test involves the following steps:

Prepare the Specimen:

Ensure that the surface of the specimen is clean, flat, and free from any

contaminants or irregularities. Visit us to learn more about Multitek’s Calibration Services

Select the Indenter

and Scale: Choose the appropriate type of indenter (diamond or ball) and

the Rockwell scale based on the material being tested and the expected hardness

range.

Apply the Preliminary

Load: Apply the minor load to the indenter, which establishes a reference

position on the specimen surface.

Apply the Additional

Load: Apply the major load to the indenter, which creates the indentation

on the specimen surface.

Release the Load:

Release the major load while maintaining the minor load, allowing the indenter

to partially retract from the specimen surface.

Measure the Depth of

Penetration: Use the depth measurement system to accurately measure the

depth of penetration of the indenter into the material.

Calculate the

Rockwell Hardness Number: Calculate the Rockwell hardness number using the

formula specified for the selected Rockwell scale.

Record the Results:

Record the Rockwell hardness number along with relevant details such as the

test conditions, specimen identification, and any observations.

Other Hardness Testing Machines available at Multitek Lab:

·

Micro Vickers or

Universal Hardness Tester

·

Brinell hardness Testing

(BHN

& LCB)

·

Rockwell

Hardness Testing (RMT-AL & RHT-LC1500-1A)

·

Rubber Hardness Testing

Machines

Advantages of the Rockwell Hardness Test

The Rockwell hardness

test offers several advantages over other hardness testing methods:

Versatility: The

Rockwell hardness test can be used to measure the hardness of a wide range of

metallic materials, including ferrous and non-ferrous metals.

Speed: The test

is relatively quick to perform, allowing for high throughput in quality control

and production environments.

Accuracy: The

Rockwell hardness test provides accurate and repeatable results, making it

suitable for precise materials testing and characterization.

Non-Destructive: Unlike

some other hardness testing methods, such as the Brinell test, the Rockwell

test is non-destructive, meaning it does not significantly alter the specimen's

properties.

Ease of Use: The test is relatively simple to perform and requires minimal training, making it accessible to operators with varying levels of expertise. Reach out to us for Microscope and Hardness Testing Machine Repair and Up gradation Services!

Applications of the Rockwell Hardness Test

The Rockwell hardness test has widespread applications

across various industries, including:

Manufacturing:

The test is commonly used for quality control and materials testing in

manufacturing processes, such as automotive, aerospace, and machinery

production.

Metalworking: The

test is used to assess the hardness of metal components, including forgings,

castings, and heat-treated parts.

Engineering: The

test helps engineers and designers select materials with suitable hardness

properties for specific applications, such as tooling, dies, and machine

components.

Construction: The

test is used to evaluate the hardness of construction materials, such as steel

beams, structural components, and concrete.

Research and

Development: The test is employed in research and development activities to

characterize the mechanical properties of new materials and alloys.

Visit us to know more about our Customized Rockwell

Hardness Test Machines

According

to Multitek Technologies the Rockwell hardness test is a versatile,

accurate, and widely used method for measuring the hardness of metallic

materials. Its simplicity, speed, and non-destructive nature make it an

invaluable tool for quality control, materials testing, and engineering

applications across various industries.

By understanding the principles, procedures, and

applications of the Rockwell hardness test, engineers and manufacturers can

ensure the quality, reliability, and performance of their products and

components. Feel Free to Contact Us, if you have any question related to Rockwell

Hardness Tester!

Automatic hardness Tester

Brinell hardness Tester

Computerized Hardness Tester

Hardness Tester

Rockwell Hardness Tester

Rubber Hardness Tester

Vickers Hardness Tester

Location:

Delhi, India

- Get link

- X

- Other Apps

Comments

Post a Comment